Product description

Ultrafit Welded AMT® Series

Antimicrobial Technology

Standard Features and Materials of Construction

- Multi-Layer, High Performance Liquid Filter Bag

- Graded Density, Composite Layer Design Technology™

- Antimicrobial agent incorporated into the final filtering layers of the bag

- 99.98% efficiency ratings (beta 5000)

- Materials of construction: 100% FDA Compliant Polypropylene

- Single-use, disposable filter bag

- Available micron ratings: 0.4, 0.6, 0.8, 1, 3, 5

Benefits of Antimicrobial Technology

- Antimicrobial agent inhibits the growth of broad spectrum bacteria, fungi, protozoa, and yeast on the treated layers

- Antimicrobial agent lasts the life of the filter

- Non-Toxic and insoluble in water

Questions & Answers AMT® Series

What are some uses for Ultrafit Welded-AMT Series High Performance Filter Bags?

When properly installed in a Filtration Systems Over-The-Top® design housing, Ultrafit Welded-AMT Series filter bags are useful in filtering many types of liquids, including water, transformer cooling oil, synthetic oil, lubricants, paints, and other water-based liquids, when prevention of fluid contamination during the filtering process is important to the final product.

Why is Antimicrobial Protection important for my filtering process?

Microorganisms can contaminate liquids causing spoilage, odor, degradation, and reduced shelf life of products. Other effects of contamination may include changes in viscosity or pH, discoloration, gassing during processing, or swelling of finished product containers.

During the filtering process the formation of biofilms may inhibit liquid flow, contaminate or corrode process piping, and affect heat exchange.

How does Antimicrobial Technology work?

Antimicrobial additives disrupt the metabolic function of thin walled, aerobic and anaerobic microorganisms, inhibiting their ability to function, grow, and reproduce on the filter media.

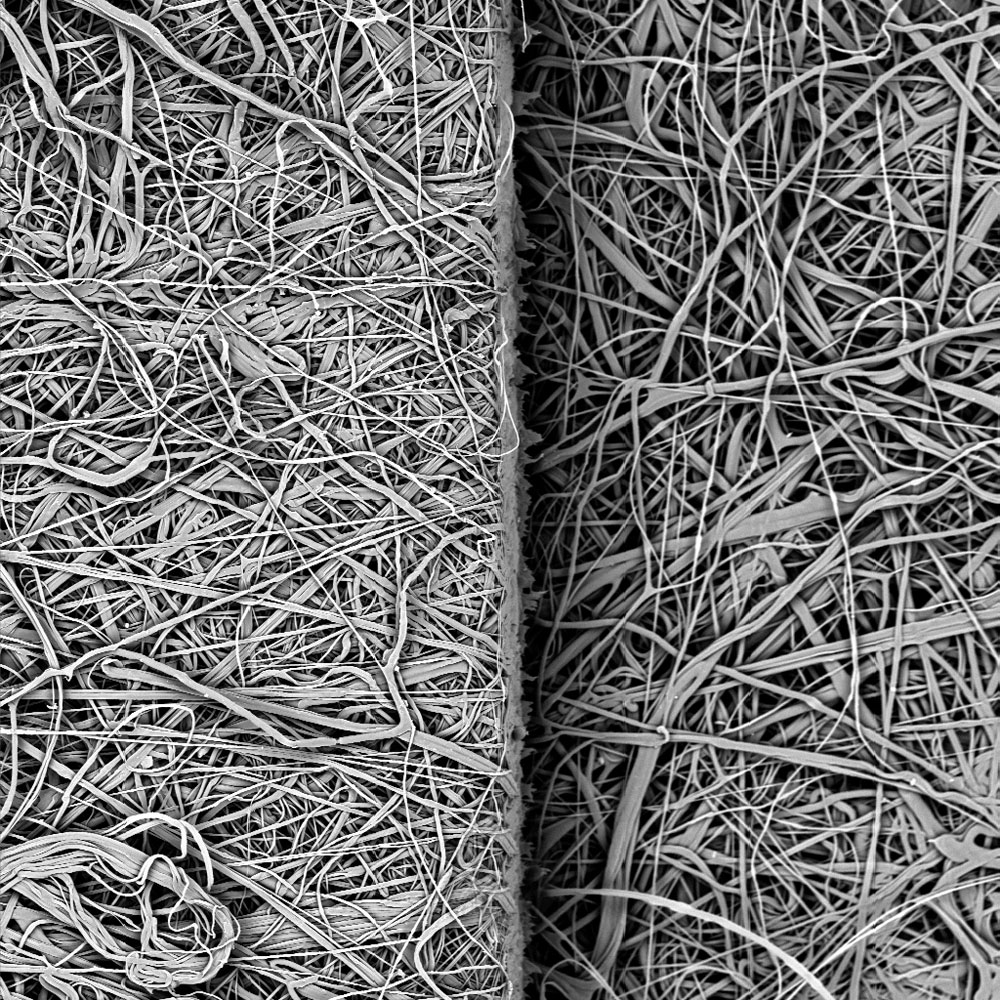

How is the Antimicrobial agent built into the media?

The antimicrobial agent is incorporated into the polymeric voids of the polypropylene fiber, without affecting the physical properties of the fiber. The submicron-sized particles migrate to the surface of the fiber, where they become an integral part of the microfiber. Since it is part of the fiber, not a surface coating, it will not wash or wear out. The antimicrobial agent is insoluble in water and lasts the life of the filter.

Is it safe?

Antimicrobial agents only attack thin-walled cells. Human and animal cells are thick-walled, and are therefore impermeable to the antibacterial additive. The antimicrobial agent, Triclosan (Chlorinated Phenoxy Compound), is registered with the EPA as a safe, non-toxic product.

NOTE: The Ultrafit Welded-AMT Filter Bag does not protect users or others against food-borne (or disease causing) bacteria. Mechanical Manufacturing Corporation, Filtration Systems Division is not making any health claims for this product.