Product description

Accufit® Welded SuperBond® & Accufit® IP Filter Bags

Multi-layer, laminated filter bags provide superior particle removal efficiencies for a broad range of industrial filtration applications…

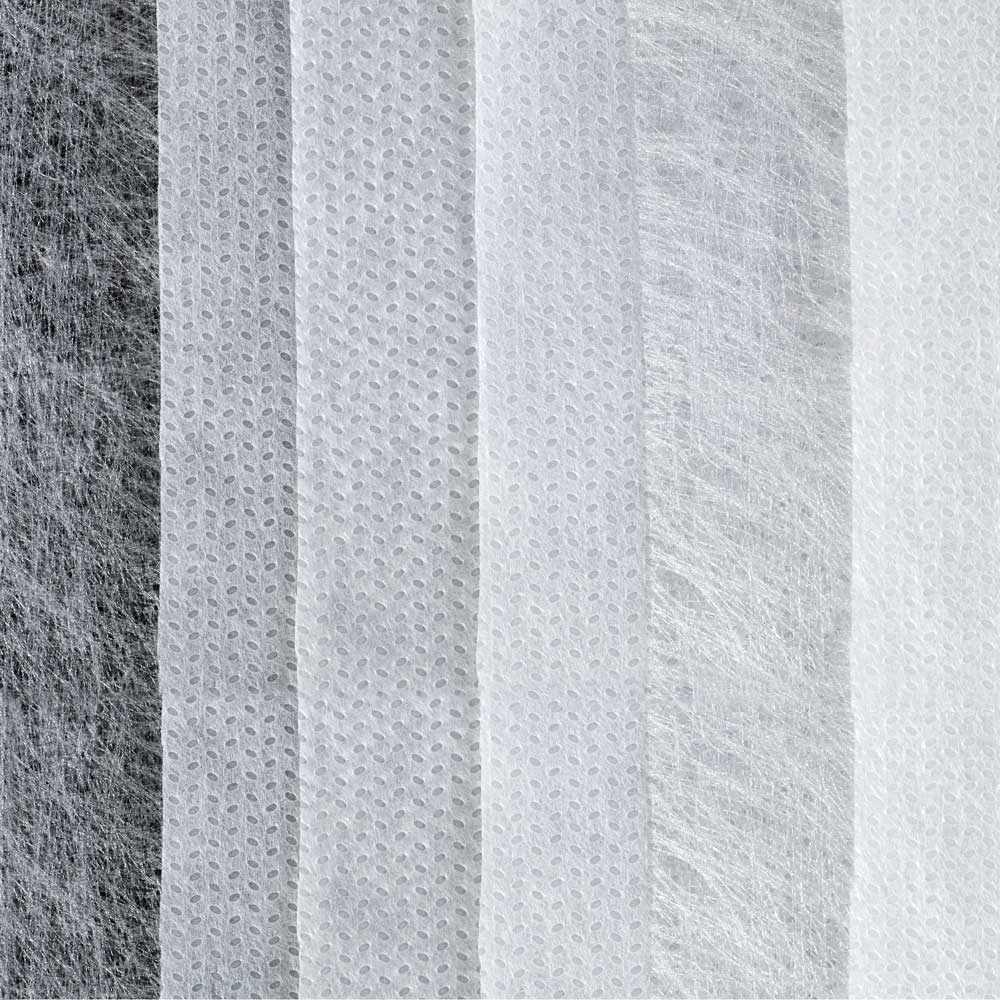

- ELC® – ENGINEERED LAMINATED COMPOSITE

- CLEAN, UNIFORM and STABLE

- DESIGNED FOR CONSISTENT AND PREDICTABLE RESULTS

- AVAILABLE IN 100% FDA COMPLIANT POLYPROPYLENE or NYLON

ACCUFIT® WELDED SUPERBOND®

FEATURES

- Accufit® Welded SuperBond® is designed as the superior alternative to commodity-grade, felt filter bags.

- Designed to provide predictable performance results with 90% efficiency ratings.

- Longer lasting with significantly improved efficiencies over and above felt filter bags.

- Ultrasonically Welded, Composite Layer Design for increased surface area and precise particle retention.

- Completely welded construction prevents solids, larger than the micron rating of the media, from bypassing the filter bag. (Conventional bags are sewn, allowing particles to bypass through the needle holes of seams.)

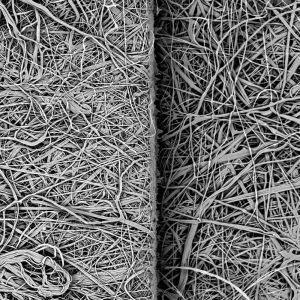

- IP Series – Integrated Polymeric Support® structural layer for enhanced strength and support. Prevents fiber migration downstream.

- A dual handle lift-out, located above the liquid level, eliminates contact with unfiltered material, allowing quick filter bag removal for replacement.

- The Zero-Bypass collar provides an optimum compression seal, when used in a Filtration Systems filter vessel. When the filter bag is under elevated pressure, the flanged bag collar prevents bypass of unfiltered liquid.

SPECIFICATIONS

- Manufactured using Multi-Layer, Thermally Bonded Continuous Filament Depth Media in Polypropylene or Nylon.

- 100% FDA compliant materials, according to CFR Title 21. Silicone free

- IP – Integrated Polymeric Support® support layer; non fiber-shedding

- Suggested maximum differential pressure: 35psi / 2.4 bar

- Maximum operating temperature: Polypropylene 180°F / 82°C, Nylon 340°F / 171°C

- Suggested maximum flow rate: 90gpm (water, P2 size)

- Available in standard industry sizes: P1 (7″dia x 16″L), P2 (7″dia x 32″L), P3 (4″dia x 9″L), P4 (4″dia x 14″L), P5 (4″dia x 24″L)

- Available micron ratings: 1, 5, 10, 25, 50, 100

MODEL NUMBER CODING

- SB-Pxxx-P2-IP (xxx = micron rating) 100% FDA POLYPROPYLENE COMPONENTS

- SB-Nxxx-P2-IP (xxx = micron rating) 100% FDA NYLON (N6) COMPONENTS

ACCUFIT® WELDED IP SERIES

- Nominally rated solids retention

- Single-use, disposable filter bag

- Supported Polypropylene Felt with exterior glazed finish minimizes fiber migration downstream

- IP Series – Integrated Polymeric Support® structural layer for enhanced strength and support. Prevents fiber migration downstream.

- Media is up to 40% thicker than most competitors felt bags

- Available micron ratings: 1, 5, 10, 25, 50, 100, 200

- 100% Polypropylene, including Zero-Bypass Collar

Media: Supported Polypropylene Felt IP Layer: Polypropylene Monofilament

Downstream Support Jacket: Polypropylene, non-woven spunbond